How To Remove A Sliding Glass Door Frame

How to Supersede a Patio Door

A new, efficient patio door stops drafts, saves energy and eliminates leaks. Learn how to do your own sliding glass door replacement.

![]() Time

Time

A full mean solar day

![]() Complexity

Complexity

Intermediate

![]() Price

Price

$101–250

Introduction

If you've been putting up with a drafty patio door that sticks, fogs upwardly or leaks during a heavy rain, it's time to consider a new, energy-efficient replacement. While a high-quality door isn't cheap, it'll cut down on drafts, crave almost no maintenance, glide smoothly and latch securely. All-time of all, you'll salvage $300-plus if you install a sliding glass door replacement yourself.

Tools Required

Materials Required

- Flexible flashing

- New sliding door

- PVC cement

- PVC sill pan

- Silicone caulk

- Woods shims

Project step-past-pace (14)

Step one

Measure out the Opening Before You lot Buy

- Pry the interior trim free.

- Chip away drywall to betrayal framing.

- Pull off the interior trim around the old door and measure the "crude opening" width (distance between studs) and elevation (floor to beam).

- Pro tip: Make sure you measure to the framing right adjacent to the old door jamb. You may accept to cut away overhanging drywall to go at it.

- To cheque the top, make sure you lot're measuring to the subfloor.

- That is, mensurate to the wood or concrete that the doorsill actually rests on and not a secondary layer of particleboard or plywood (underlayment).

- Select a new sliding glass door that fits your crude opening.

- Pro tip: Once y'all go your door abode, yous'll save a lot of time if yous finish whatsoever exposed wood surfaces on the door earlier outset the installation.

Stride ii

Remove Onetime Sliding Glass Door From Frame

- Latch the door, then unscrew and remove the inside head end.

- Unlatch the door, tip the height of the sliding panel in and lift information technology free of the rails.

Step 3

Remove Angle Brackets

- Unscrew and remove any angle brackets at the elevation and bottom of the stationary panel.

Step 4

Remove the Stationary Panel

- Pry the stationary console complimentary of the frame at the summit and bottom, slitting caulk or paint as necessary with a utility knife.

- Tip it inward and lift information technology complimentary.

Step 5

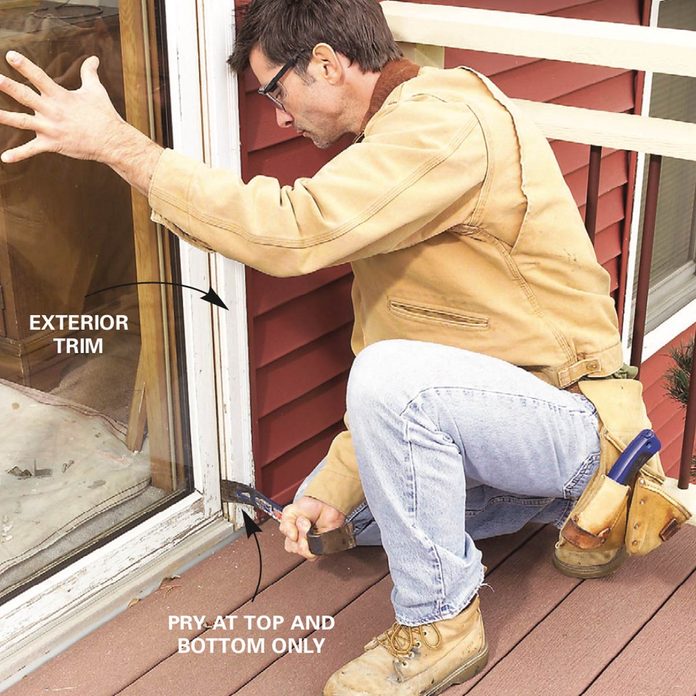

Remove the One-time Sliding Door Frame

- Pry off the outside trim.

- Use a reciprocating saw with a longer bimetal blade to cut between the framing and the door jamb.

- You will cutting through the insulation, fasteners and shims.

- With the head and side jambs cut gratis, tip the frame from the elevation to the outside.

- Pro tip: Most likely, the threshold will be glued to the floor with chaplet of sealant, and it may have substantial prying with a flat bar to free it.

- Once the frame is out of the opening, cutting it into chunks for disposal.

Pace 6

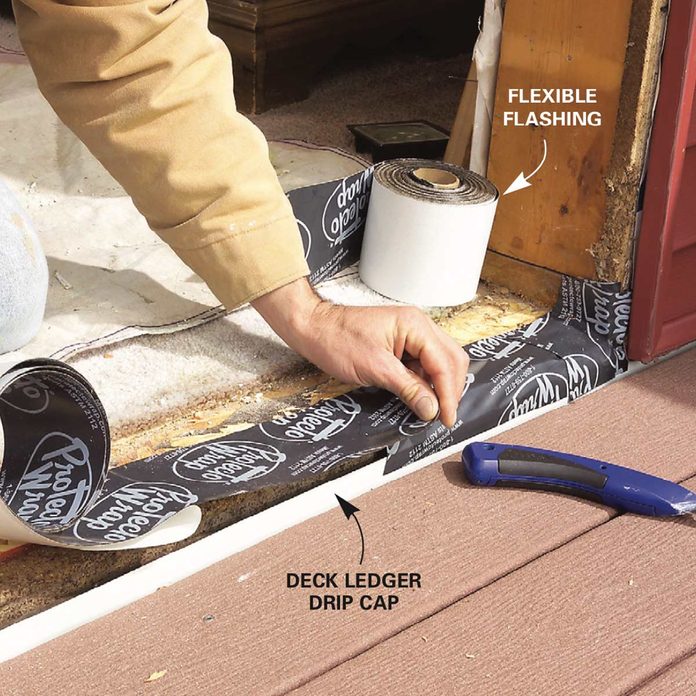

Employ Flexible Leakproof Flashing

- Brainstorm flashing at the bottom.

- Employ flexible flashing directly under the doorsill and two inches up the sides.

- Flexible flashing comes in 4- to half dozen-in.-wide rolls and has a sticky side so it adheres to the underlying surfaces.

- It's imperative that the flashing laps well over any deck flashing or weather barrier below the door.

- You may accept to overlap two rows to get the necessary coverage.

Footstep 7

Install Sill Pan

- Pros volition unremarkably residual the new doorsill (caulked) directly on the flashing, merely for further protection in moisture locations (rain volition splash confronting the door bottom from all angles), add a "sill pan" as well.

- Make clean the joint overlaps with PVC cleaner, then lay the parts in identify and weld the seams with PVC cement.

- Earlier y'all brainstorm flashing, check the floor for level. In rare situations, the flooring under the door will exist out of level.

- Sweep the floor free of droppings and bank check it with a direct board and a four-ft. level.

- Pro tip: If it'due south within 1/4 in. of level over the half-dozen-ft. opening, let information technology exist; the door should still slide smoothly. Simply right larger variations with two long, tapered shims placed directly under the sill (use treated woods on physical).

- Fill any voids with polyurethane caulk to proceed out drafts. Then continue with the flashing.

Step 8

New Door Flashing Details

The key to making your sliding door leakproof is to carefully follow the proper flashing techniques.

- The basic principle is to continually keep h2o flowing down to the outside. In nigh cases, you lot tin follow the details we prove here for flashing the sill. The side details will vary depending on the new door frame details and the exterior siding on your home.

- Most doors take plastic nailing flanges ("fins") that you lay over some type of firm wrap. Extend the house wrap if necessary.

- And then lay adhesive-backed flexible flashing over the flange/firm wrap joint to seal it.

- Stop the sides by nailing on the side trim and caulking the gaps.

- The peak details vary slightly. If you demand a trim piece at the top, slide a metal baste cap nether the house wrap and nail the trim directly beneath information technology.

- If you lot don't demand an extra trim piece, slide the nailing flange under the house wrap, seal it with flexible flashing, and lay the house wrap over it, sealing the corners with small-scale sections of flexible flashing.

- The peak details vary slightly. If you demand a trim piece at the top, slide a metal baste cap nether the house wrap and nail the trim directly beneath information technology.

Step 9

Caulk and Install the New Sliding Door Frame

- Gather the frame following the manufacturer's instructions.

- If yous have a "knockdown" (not preassembled) door frame, assemble it on the deck, garage flooring or other flat surface.

- "Dry-fit" the assembled door frame in the opening to brand sure everything fits.

- Apply two beads of silicone caulk along the length of the threshold and tip the frame into the opening.

Step ten

Square and Fasten the Frame

- Center the frame in the opening and spiral it into place, using a level and shims to square it.

- Bank check the frame for square and make last adjustments when you install the stationary panel.

Step xi

Tip in the Glass Panels

- Tip the stationary panel into the opening, push button it confronting the door frame and install whatsoever bending brackets to anchor it.

- Tip the operable panel into place and spiral the within head stop to the pinnacle of the door frame.

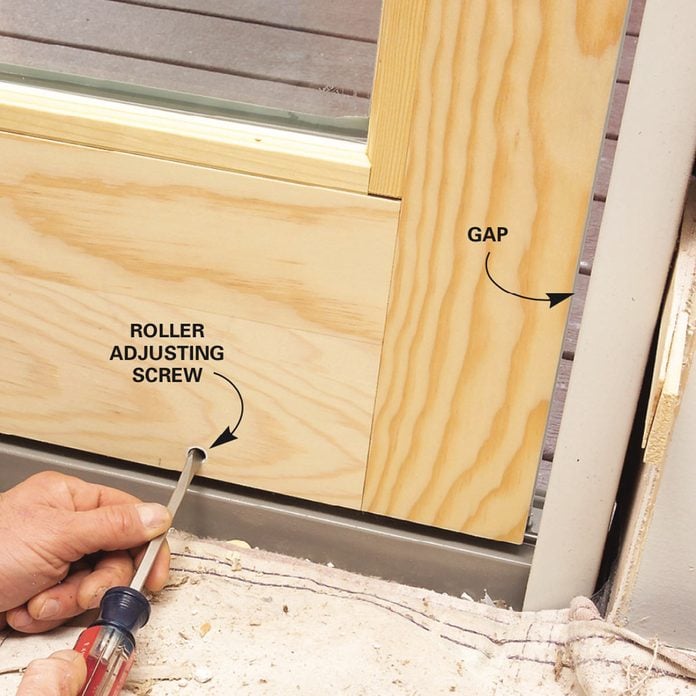

Step 12

Conform the Door

- Slide the door slightly open and suit the roller heights until the gap between the jamb and the panel is consistent.

- Installing your new slider is ordinarily the easiest part of the job.

- Finish up past installing the handle and the locking hardware.

Stride 13

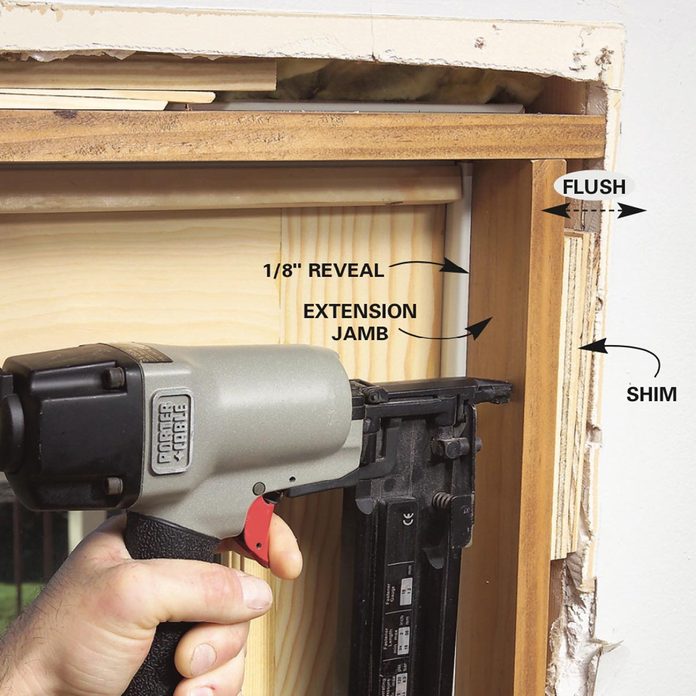

Finish Up on the Inside

- Standard slider doorjamb depths are designed to fit standard four-9/16-in. or 6-9/16-in. thick walls (2x4 or 2x6 studs plus 1/2-in. drywall and capsule).

- If your walls are thicker, yous'll have to add extension jambs.

- Cutting the top slice to fit kickoff, and then shim it and boom it in place.

- Then install the side extension jambs.

- Go out an fifty-fifty 1/8-in. reveal (backset) between the extension jamb and the doorjamb.

- Insulate around the frame with fiberglass packed tightly confronting the outside sheathing and more loosely almost the drywall.

- Note: Foam insulation is more hard to use because even minimal expanding types tin bow in jambs and affect weatherproofing or door operation.

- Add interior trim effectually the door, leaving some other ane/8-in. backset between the trim and the extension jambs.

Step xiv

Finish Upwards on the Outside

- Cut filler strips to fit between the door frame and the siding with a 1/8-in. gap on both sides, then fill the gaps with silicone caulk.

- Cut a threshold support block to fit betwixt the deck and the siding, and so slip information technology into place and nail it.

- Pro tip: Yous'll oftentimes be installing a door that's smaller than the i y'all removed. This will leave a wider gap that you'll take to fill with exterior trim.

- Match the new trim to the existing as much as possible.

- Whatever trim you cull, rip the trim slightly narrow so you leave i/8-in. gaps on both sides.

- Seal these gaps with a high-quality acrylic or silicone caulk.

- Finish upwards your installation by screwing or nailing a 3/4- to 1-in.-thick piece of cedar, treated wood or blended material directly nether the overhanging lip of the threshold to back up information technology.

- Some sliding door manufacturers offer a pre-made aluminum support strip equally an alternative.

Originally Published: May 19, 2022

How To Remove A Sliding Glass Door Frame,

Source: https://www.familyhandyman.com/project/replace-a-patio-door/

Posted by: olveradoull1966.blogspot.com

0 Response to "How To Remove A Sliding Glass Door Frame"

Post a Comment